i4 Product Design Business Director Tristan Elliot offers a few ideas for your product.

i4pd Director Tristan Elliot is no stranger to helping turn a great idea into an even greater product.

In his role at i4pd he focuses on effective collaboration for a great customer experience where he liaises with customers and the i4pd development team, challenging thinking and decision-making, to ensure the journey runs smoothly from initial concept to a production-ready design.

As part of our partnership with Scotland's Converge Challenge, Tristan presented his Top Tips for Effective Design to a group of Converge entrepreneurs.

Since 2003 i4 Product Design has been a development partner for start-ups and well-known brands helping to bring over 200 products to market during this time. The firm is Employee-Owned and was awarded the 2018 ‘Engineering Company of the Year’ Made in Scotland award.

Schedule a call today with Tristan to see how the i4pd can help realise your vision.

TOP TIP #1:

Shoot for the stars but be careful who is in charge of designing of your rocket…

Example 1:

Company has the vision to build the world’s best multi-use spaceships.

To illustrate at a very high level how important to the success of a product the selection, leadership and integration of your core development team is I’ve used this following hypothetical vision for a space company.

The company set themselves the challenge to build the world’s best multi-use spaceships. Money was no obstacle for them so they poached the principal industrial designer of a supercar company who had never designed a rocket before. He was given full creative control and led the project from the start.

|

Example 2:

Company hired a design house with minimal plastic design experience to develop a water/shockproof housing for an industrial remote control.

Fundamental design flaws

Design from original design house:

We took on the project and had the unfortunate job of telling the company the design could not be saved if it was to be waterproof and shock resistant.

Meant throwing away an expensive injection moulding tool for making the enclosure

We redesigned the product according to the fundamental design principals of Ingress Protection and carried out verification testing prior to tooling which was not done by the previous designers.

The previous company should have been asked what their experience was with the sealing of plastic enclosures and if they could get references from companies who they had successfully delivered similar projects for.

Design by i4pd

TOP TIP #2:

Base decisions around the 2 key things that keep you up at night (related to your project!)

Unfortunately in the world we live in resources are finite and you will have to make a lot of compromises and sacrifices along the way to get to market with your product.

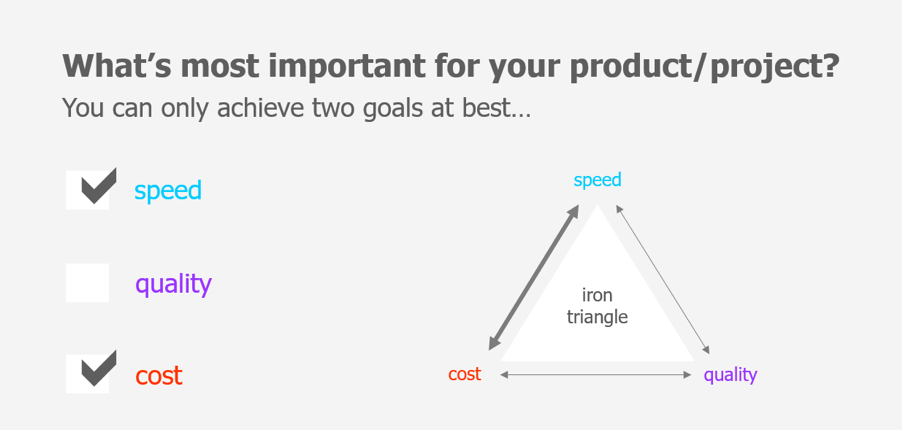

The 3 critical constraints of any project are speed to market, quality of the final output and the cost of the development and/or product offering itself.

You will likely have to sacrifice one of these so be upfront with yourself as to which one it is really a “nice to have” as this will guide your design strategy and decisions.

I’m going to break down this tip now further to highlight how you can achieve each these constraints and the associated trade-offs you will have to make.

speed: what are my options?

|

1) Hire lots of designers and engineers (if you are lucky enough to have the funds to do so!) |

|

|

= More ideas, more output |

= Less efficient, less cost effective with duplication of effort and potentially more time idle waiting for other parts of the project to catch-up. |

|

2) Remove limits on production cost of the product Could allow you to opt for off the shelf mechanical components, electronic modules and software libraries. You would also potentially not have to invest as much time in the product’s design for manufacture and assembly which can be a significant proportion of a design budget. |

|

|

= Less effort achieve design requirements |

= Potentially expensive product using off-the-shelf designs |

|

3) Fewer prototyping/testing rounds Removing iterative prototyping from the plan is a plan for failure. |

|

|

= Cuts months from your development time |

= Risk to quality and failures in regulatory testing |

|

4) Base your fundraising around a plan broken into stages where you will have tangible deliverables along the way (ETP, ESP & ELP) Often the best option is to integrate your fundraising strategy with your development plan where you brake the project into stages where you will have tangible deliverables along the way such as an earliest testable product, Earliest sellable product and finally an earliest lovable product. This won’t speed up the development overall but it will allow you to demonstrate tangible results to your stakeholders quickly. |

|

costs: what are my options?

|

1) Use a mix of in-house hires and contractors/partners. There will be certain skills/disciplines are you always going to need such as data analytics and software development but you may only need to develop the hardware once to support the data acquisition. Hire in those essential long term staff and contract out the rest where you can only see peaks and troughs of work in the future. With consultants you’re not paying consultants for the day or month of their work. What you are paying them for is the 10+ years they have been spent honing their skills so they tend to be more efficient. Also if you opt to work with a consultancy over a freelancer any mistakes should be spotted by their internal review procedures before they cause an effect on budget and timelines which could happen if no such checks are available of in-house staff. Costs can be offset by the next tip option below. |

|

|

= Saves money during troughs and get experienced people so timelines kept with no reworks |

= More expensive particularly than graduates |

|

2) Offer equity or royalties to the designers/engineers to offset all or part of their design costs. |

|

|

= Reduction/elimination of upfront costs |

= Affects margin of your product and investors need to be on board with this strategy |

|

3) Decide what product features are a ‘Nice to Have’ with a product roadmap

Break down your product into a list of features and rate them as essential or nice to have. Get companies to quote on all of these and develop a roadmap for introduction of the non-essential features at a later date if the total budget is unachievable. Once you are revenue generating you can then look at including those features. My advice is to do this as early as you can! Depending on how far along you are along the development before you undertake this exercise you might end up disappointing some key stakeholders with your decisions not to include certain features. |

|

|

= Focuses funding towards an essential product |

= You might not have what you initially promised investors or customers |

quality: what are my options?

Quality is typically the last thing that keeps people up at night but this shouldn’t be the case.

Quality suffers at the expense of lesser resources and time made available for development as these are felt by companies more acutely during the development itself.

There are always creative ways to extend budgets and timelines but it’s not so easy to short change the quality of a project.

|

1) Don’t take short cuts when it comes to prototyping. Time and time again I see it in people’s plans… Don’t skimp on prototyping. You can get away with development kits for electronics almost indefinably sometimes but when it comes to mechanical prototypes, you often need to move away from 3D prints to higher fidelity processes like CNC, vacuum casting or even prototype injection mould tools. |

|

|

= More robust product when it gets into the hands of expensive test houses and customers |

= Time + money |

|

2) There is no substitute for experience (in all areas). Work with people that have gone through the entire design and development process (not just a part of it). Get them to back up their words with physical examples of their work as highlighted in the previous tip. |

|

|

= Speed and effectiveness of the output |

= Greater budget than graduate/junior level |

|

3) Find a way to get independent design reviews. So if you are hiring in all the expertise you need in-house but only have one of each discipline, ask them will they be OK working in isolation. Find out if they have worked in a similar way previously with no oversight. Ideally find a way you can get independent design reviews through means of advisors (paid or unpaid) as sometimes even obvious mistakes creep in when you work alone. |

|

|

= No mistakes! |

= May cost you to undertake these reviews |

TOP TIP #3:

Don’t overthink it.

Again, this is really a couple of tips in one.

Minimal designs work best for the user on many fronts. Particularly on intuitiveness and usability of a product. The famous German Designer Dieter Rams’ motto was, “Weniger, aber besser” which translates to “Less, but better”. It influenced his own work but also the work of some of the most well-recognized designers, including Apple’s former SVP of Design, Jony Ive. In Apple’s line of iPods, iPhones, iPads, and Macs, Ive’s minimalist style closely mirrors the work and principles of Dieter Rams, sharing a similar, simplistic design methodology.

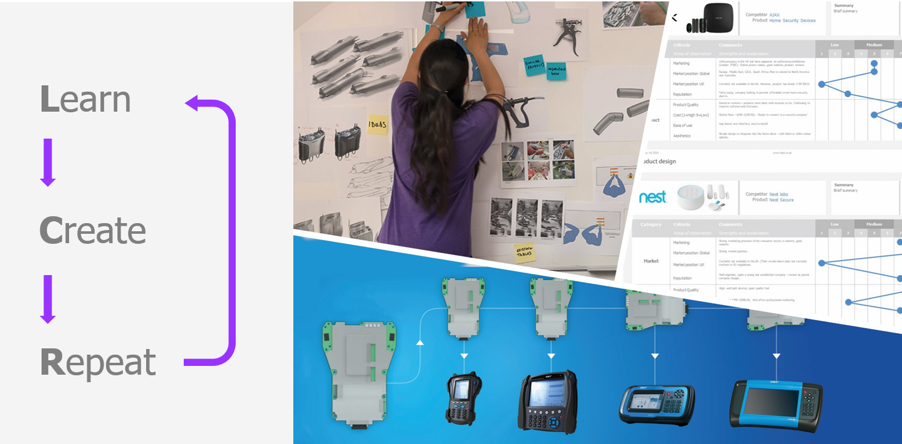

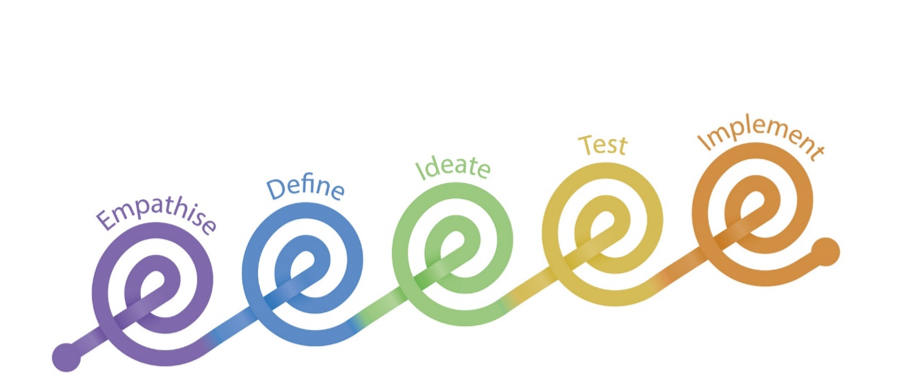

The second part of the ‘keep it simple’ advice is to try and stick with a series of little design experiments while you can in the design process.

At some point you will need to have an all-in-one product but to try and pull this off at the start can be too complicated.

Where it’s possible to section off and create and test parts of the product can yield better quality technical and user feedback. This agile process allows you to be more user centred and flexible in your approach to the development.

An initial phase of speaking with your target market about your idea and listening to their responses. Turning these wants and needs into a preliminary set of requirements that you can then design and create a low fidelity prototype of.

Then learn from that prototype by putting it into the hands of your user and other key stakeholders.

The number of times you have to repeat the process is often down to how complicated the needs are of the end user, how regulated the market is that you operate in and whether you value speed to market and/or cost over quality.

Copyright © 2024 i4 Product Design Ltd. All rights reserved. | Privacy Policy