Our relationship with Shot Scope began when CEO David Hunter selected i4pd in 2016 to develop its next generation GPS golf watch – Shot Scope V2. We were challenged to design, engineer and support the manufacture of the device within eight months, ready for a 2017 summer launch.

Following the success of V2, a sell-out pre-sale campaign which attracted more than 5,000 users across 42 countries, the launch of the V3 watch had been highly anticipated. This time the product sold-out (25,000 units) within a few weeks.

Here’s how we approached the design.

The original Shot Scope system was a wrist worn device with a ‘Club Sense’ system, able to record the user’s exact point on the course where the ball was played, detect which club has been and the associated shot distance.

The 'V2' combined this proven tracking technology with an integrated GPS range finder system which indicates the distance to the green on each hole as well as the position of difficult obstacles.

Shot Scope's V3 smart GPS watch is designed to be the culmination of customer feedback on the V2, and its predecessor. This variant had to take the product from a low/medium volume niche ‘interesting piece of Tech’ to be a mainstream consumer product to take on the established players in the marketplace.

Watch the full discussion between Shot Scope and the i4pd team about their partnership

Here are the challenges we met:

Much like the V2 design, focus was again on the straps. Not only was an internal antenna required, but they also had to be interchangeable for customer customisation. Architecture concepts were created with input from Shot Scope and their manufacturing partner.

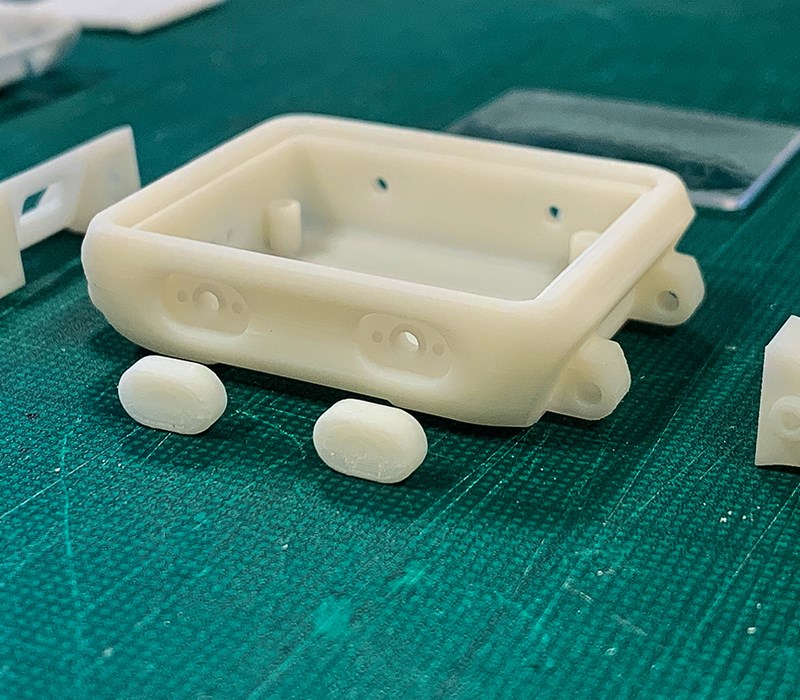

Using the i4pd studio’s lab, in-house 3D prints quickly allowed for previewing the size and form of the proposed design/‘A’ surface CAD. This also enabled variations of individual components to be prototyped and tested quickly without impacting the overall timescales such as the buckle clasp with differing lengths.

Once the design for the engineering stage was nearly complete, high-resolution 3D prints were produced, allowing assembly tests to be conducted as well as Human-Factor testing for ergonomics. Rubber like 3D print material was used to prototype the straps which gave promising feedback.

Right from the start of the project, i4pd were in close communications with Shot Scope’s preferred manufacturing partner. This meant that from the beginning tooling capabilities were known and resulted in a robust and well considered design from the start. Architecture concepts were shared with them and they provided valuable feedback.

The main body has an over moulding process & twin shot tooling. The charging pins to the ABS body substrate, and then the second shot moulding of ABS acting as a colour break (initially it was to be TPE over-mould).

The straps also have an over-mould process with the ABS strap mounts and antenna assembled to one half of the silicone strap and the second shot of silicone on top. i4pd provided constant support for the design data pack to the client and manufacturing team

We like to find new, better and efficient ways of doing things. Contact us to discover how i4 Product Design can solve your current design challenge and take your product to the next level.

Copyright © 2024 i4 Product Design Ltd. All rights reserved. | Privacy Policy